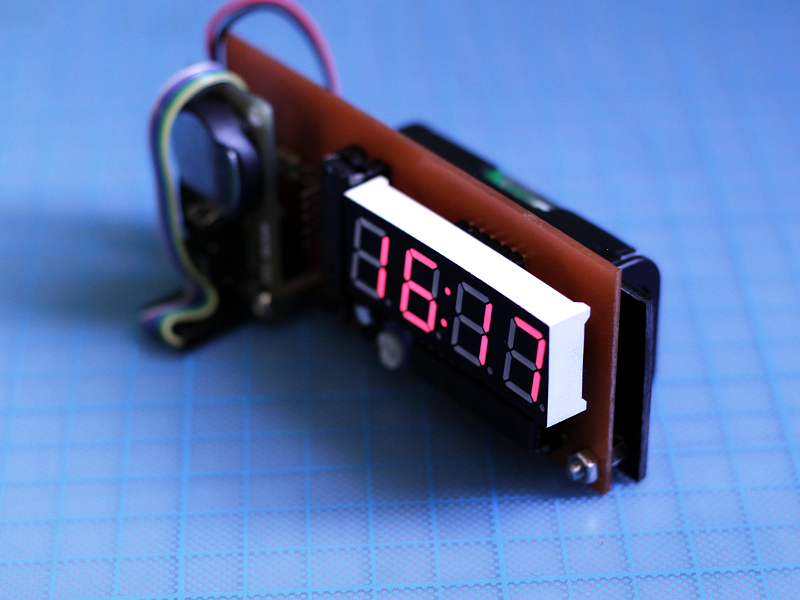

You may remember the small soldering fume extractor I designed a while ago. It has worked really well since I built it, and it’s made my soldering work a much more pleasant experience.

However, during the time I’ve been using it, I’ve discovered a small aspect that could definitely be improved. Because of the way it works, when the fan start working it “sucks” the carbon filter a bit towards the blades. As the distance between the filter and the fan blades is no more than 2mm and the filter itself is not rigid, the carbon surface “bends” and touches the spinning fan, which causes the blades to pull and cut fibers from the filter. You can actually hear this happening when you turn the unit on with a reasonably new filter.

This stops after some uses, as the filter becomes thinner and less dense from all the fibers it has lost. This doesn’t prevent the extractor from working, but it certainly reduces both the efficiency and the lifespan of the filter.

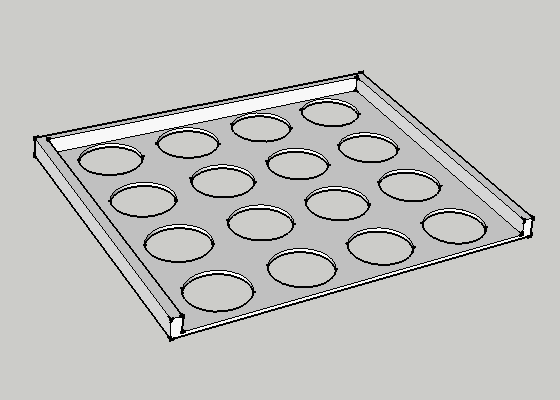

To solve this I designed a small plastic “grill” that would hold the carbon filter in place, separating it from the fan.

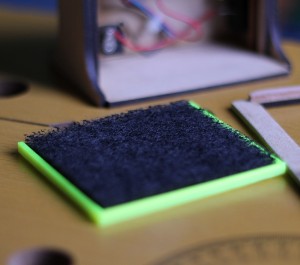

I 3D-printed this piece at a local hackerspace and installed it on my soldering fume extractor, and this is the result (Fluorescent yellow/green was the only available filament when I went to 3D print. Hopefully it doesn’t glow in the dark):

With this solution the filter is able to resist the “suction” created by the fan and no longer gets in the way of the blades. And as it’s not constantly losing strands and layers of tissue, it should filter fumes properly for longer, without needing to be replaced as often as it used to.

If you built the extractor (or were planning on making or designing one yourself) I’d definitely recommend you to have something like this in place. You can click here to download the Sketch-Up model and the STL file for 3D-printing.